How Polishing Pads Work With Cerium

Take a Shine to Your Glass

Polishing pads are simply carriers for your cerium oxide slurry. They provide a substrate to hold the cerium and provide friction between your glass and the cerium slurry. We offer two main types of polishing pads; a perforated synthetic felt material and an extruded urethane material.

It's Not a Cork Board

The LP66 material may look like a cork material, but it's an extruded urethane made in large blocks. The center section of the block is cut out to form the LP66 polishing material.

The LP66 is a dense hydrophobic material, which means it will hold its form and not dish out as quickly as a softer polishing substrate, and it will repel water while grabbing onto the cerium for a fast, efficient polishing material.

The added advantage of the denser structure is that it will retain crisp edges when polishing and won't tend to round off the edges like a softer material will.

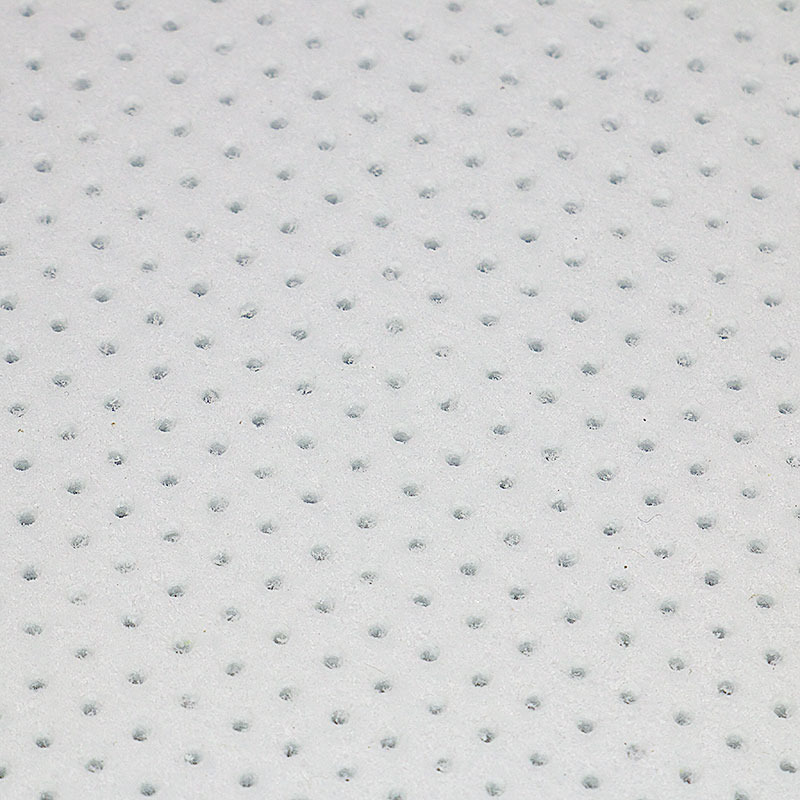

Hole-y Felt Pads!

Our synthetic felt pads are an optical felt material with small, uniform perforations on the material's surface.

The synthetic felt fibers help to hold the cerium particles, and the natural weave of the fabric allows water to flush through the material while retaining the cerium particles. The perforations provide a break in the material's surface tension and help prevent suction on the pad's surface. They also assist in providing friction between the cerium and your glass for optimal polishing.

The synthetic felt material is softer than the LP66 material, so it will push into areas more and cause more edge rounding on sharp edges during the polish stage. It will also have more friction "grab" than the LP66.

All Charged Up

Polishing pads by themselves will not polish your glass. They are just carriers for the cerium oxide element. You must charge your pad before and during use to adequately and efficiently polish your glass. We recommend making a thin mud consistency of a small amount of cerium and spreading that over the surface of your polishing pad when you first receive it. Allow that to dry overnight, and then use your pad with water the next day.

Mix 2 parts water with 1 part cerium in a small squirt bottle and squirt small amounts in the center of your polishing pad as you work to achieve your polish. Use just enough water to keep your pad moist as you work so you don’t burn the cerium onto your glass. Don’t overuse cerium, as too much cerium will act as a lubricant instead of a polish.

Glazed and Confused

Cerium slurry can build up over time on a polishing pad and glaze over the surface, preventing an efficient polish on your glass.

You can break up the surface of a Synthetic Felt Pad with the tines of a fork while the pad is moving on the grinder, and the LP66 pad can be surface dressed with a diamond dresser while the pad is running on the grinder.

Occasional dressing of polishing pads will help you polish your pieces more efficiently with less cerium usage. It can often be confusing why your polishing pad is suddenly not polishing, and cerium glazing is almost always the culprit.

Login and Registration Form