Hand Grinding Pads

Which pad is the best choice for your process?

Hand pads or handipads? Electroplated diamond or resin diamond? It can be daunting to figure out which pads are the best choice for your particular process. Let's break down the options so you'll better understand how they work.

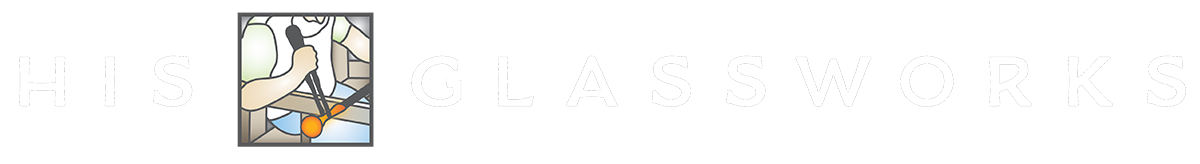

Electroplated Diamond Hand Pads

Electroplated diamonds will be the most aggressive style handpad you can use. They range in grit from rough at 60 grit to fine at 1800 grit. Don't be fooled, though. Even at 1800 grit, the surface an electroplated diamond will leave on your glass is still too rough to polish (although you can fire polish from this grit).

Electroplated diamond hand pads are best used to remove material from a larger surface. The thicker foam pad allows for a firm grip on the pad for making longer strokes of lengthy material or wider arcs on larger surface areas.

3M Electroplated Diamond Hand Strips

The electroplated diamond hand strips are not different from the electroplated diamond hand pads listed above. They still offer the removal of material from surfaces quickly and efficiently. Still, they are meant to be mounted onto a foam hand block, allowing for much more force and pressure on the glass surface for faster removal.

While they are meant to be used with a foam hand block, these are velcro-backed and somewhat flexible, so they can be used to wrap around holders to get into difficult-to-reach around other to areas if necessary.

3M Electroplated Diamond Handipads

If you need to work smaller areas, or curves, then the diamond hand pads and blocks are going to be too firm to work with.

Enter the Diamond Handipad. Our smaller 2-1/2 inch x 2-1/2 inch diamond pads on a thinner foam backing. The electroplated diamond handipads work the same as the above hand pads with quick removal and finishing work on the glass surface, but still too aggressive to be polished from, even at the lower 800-grit pad.

What do I use for a pre-polish finish?

While the electroplated diamonds cannot give you a pre-polish finish, even at finer grits like 800 or 1800 grit, moving to a resin-bonded diamond structure will be able to achieve a fine enough finish to polish.

One of the biggest confusion points is that the resin-bonded diamond can go down to a 100-grit diamond. It should be very aggressive, remove much glass material from the surface, and keep going.

But the diamond is bonded in a resin and not in nickel.

The resin is a softer format, and if you try to rough grind, the surface of the glass is often uneven enough to wear down the resin and release the diamond. Resin-based diamond pads are only used for light-duty removal or cleaning up from a surface that has already been prepped with an electroplated diamond.

You can go from a 200-grit electroplated to a 220-grit resin diamond. You can also easily polish from a 325-grit resin diamond finish.

Resin Diamond Hand Blocks

The Resin Diamond Hand Blocks are made to move your rough ground glass surfaces to a pre-polish finish. Used after the electroplated diamonds to give a finer surface on the glass, these pads will not do any heavy removal on their own, even at rougher grits like 100-grit.

They can be used on their own for light surface work and blemish removal, but are mostly used in conjunction with the electroplated diamonds to move from a rough surface to a pre-polish finish.

Resin Diamond Handipads

For smaller surface areas or areas that need more controlled grinding, we also have our resin diamond material in the smaller 2-1/2 inch x 2-1/2 inch Handipad format with a flexible foam backing.

Made to easily grind curves or smaller areas, these resin-based diamond pads are the perfect complement to the electroplated diamond hand pads listed above.

What about the final polish?

Excellent question.

While we always recommend trying to polish a glass surface mechanically, we have the option of hand-polishing your glass as well.

Cerium requires a chemical reaction with the cerium and the silica and a physical reaction of friction between the cerium and the glass surface. This friction is much easier to achieve mechanically, but 3M also makes a cerium Trizact material, which has tiny pyramids of cerium on the material's surface. The pyramids allow quick friction between the cerium and the glass, even when used by hand.

To match the formats of the pads above, we make 3M Cerium impregnated material in a Hand Block format and a Handipad format.

Login and Registration Form