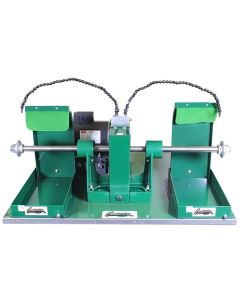

Covington 4012 Lathe Walkthrough

Affordable and Powerful

If you're looking for a lower-cost, adaptable, powerful lathe for your cutting needs in the cold shop, the Covington tabletop 4012 and its sister lathe, the free-standing 4013 lathes, are some of the best choices.

With the ability to run wheels on either side of the double-sided shaft along with any screw-mount tool like the electroplated or resin diamond cones and domes, the 4012 and 4013 lathes are an excellent choice for a budget-minded shop that still wants high quality, workhorse equipment.

What's Different About the Professional Lathe?

In addition to the 4012 and 4013 glass lathes, Covington also makes a 4000GL Professional lathe. So what's the difference in these besides the price?

The 4012 and 4013 are double-sided shafts so you can put wheels on either side of the lathe. This also gives the shaft more run-out than the single shaft 4000GL. For most cutting, the run-out on the 4012 and 4013 shafts will not make a big difference, but if your pieces are all worked on the lathe and they depend on the highest tolerance, then the 4000GL lathe may be the better option for you in terms of wheel and shaft stability.

Cutting Or Engraving

The most common use for most lathes is for heavy cutting of your glass, from punty removal to battuto surfacing on the glass.

These are often accomplished with radius profile wheels in either electroplated or sintered diamond. These lathes are excellent for working with radiused diamond wheels, moving from rough cutting to polish on a single machine.

Lathes are also perfect for engraving with sintered diamond wheels in a V-groove miter profile or Full Circle, Olive cut profile. While the 4012 and 4013 lathes will work with engraving, the runout on the shaft will give a little more "bounce" to the engraving wheel and make precision cutting a little more complicated.

Login and Registration Form