His Glassworks 4 x 106 Inch Wet Belt Sander

What Makes a Wet Belt Sander?

While plenty of wet belt sanders are on the market, most are geared towards the flat glass industry and less towards the art glass industry. They are built mainly for edging glass panels, and while our wet belt sanders will also work perfectly for flat glass edging, we also designed them to work better for the standard glass artist.

If we had a choice of cold shop equipment to outfit our first coldshop with, it would be, first and foremost, a wet belt sander, followed by a wet saw and a flat lap grinder. Wet belt sanders are versatile, from working entire surfaces to edges, rounds, and facets. They are some of the most capable machines in your coldworking arsenal.

Roll Away

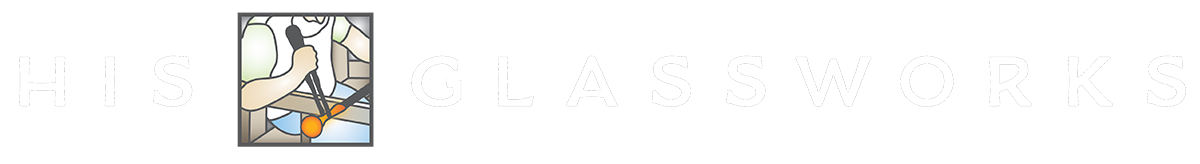

Wet belt sanders will come with a roller bar made to edge large panels of glass quickly. If you're working with fused glass, this can be great to easily keep your pieces moving along the edge against the abrasive belt.

If you're not edging glass, this bar can be in the way of accessing the roller platen and the belt. On our wet belt sander, you can remove the three bolts along the roller bar's side and remove the entire assembly from the sander, granting you unfettered access to the belt surface.

Open UP

For safety, our wet belt sander comes with a metal belt guard on the upper portion and a plastic belt guard on the lower portion. The plastic belt guard can be raised and lowered to cover or expose a more significant portion of the abrasive belt above the roller platen.

Removing the thumbscrew removes the plastic belt guard from your sander. If you need more access to the top part of the abrasive belt on your belt sander, you can remove the side bolts and top bolts from the metal belt guard and altogether remove it for full access to the belt from the roller platen up to the top roller.

Lock it Down

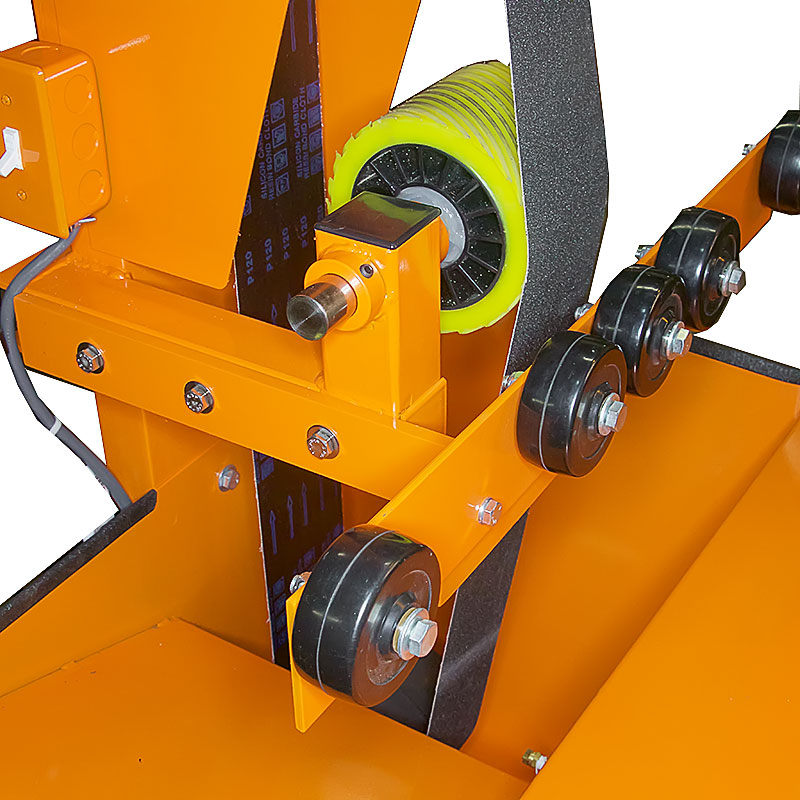

In a new addition from our video above, our tension arm now has a "tension lock" added to keep the tension arm in the "down" position more easily while changing belts. This prevents you from holding the tension arm down the entire time while you try to add or remove a belt from the sander.

Pull the tension arm down, then pull out the T-bar handle on the tension lock, rotate it 90 degrees, and let the spring-loaded lock fit into the hole on the tension arm. Let go of the tension arm, and it will hold in place.

Add or remove your belt, pull down on the tension arm to relieve the pressure on the lock, pull out the T-bar handle, rotate 90 degrees, and rest the lock in the "off" position. Release the tension arm to apply the correct tension to your belt.

Be sure to pull down on the tension arm when releasing the tension lock to prevent damaging the T-bar handle on the tension lock.

Regular or Stainless?

Our standard water basin on the wet belt sander is regular steel. On these units, we attach a sacrificial anode in the water basin. This anode will rust and degrade over time, so use it to keep your regular steel water basin virtually rust-free. If the anode completely corrodes, we can get a replacement anode for your water basin. However, this typically will take several years of heavy use before you need to replace your anode.

Opt for our stainless steel water basin if you are in an area prone to high rust and corrosion. This will keep your water basin from ever experiencing rust or corrosion over the long term, with no need for an anode.

Belt Choices

We have several choices regarding abrasive belts you can use with your upright belt sander. From economical to long-lasting, we have various high-quality belts for all your grinding needs.

The most commonly used abrasive belts are our silicon carbide belts. With a sharp abrasive that quickly grinds the glass, these are the most economical belts for most grinding situations.

We offer electroplated diamond belts with a high cut rate and consistent life for heavy and long-term use. They do come at a much higher price point, but if you constantly use a particular grit and seem to be wearing out the silicon carbide belts, these are a great choice.

Trizact Belts are an aluminum oxide abrasive and work well for fine surfaces and pre-polish work on your glass. They leave a fantastic surface on the glass quickly and efficiently.

For longer life and a more consistent cut rate, the resin diamond belts are excellent for pre-polish work on your glass surfaces.

Login and Registration Form