Covington 4000GL Professional Lathe Walkthrough

What Makes a Professional Lathe?

What are the differences between various types of lathes that make one more "professional" than the other?

Tolerance of the shaft is one if the most significant things to look for on your lathe. While grinding and polishing will not require high lathe tolerance, it can make more precise work more manageable and less prone to "chatter" from your grinding wheels. Less expensive lathes will work quite well for most everyday grinding needs, but for the most precise work with less wear on your grinding wheels, a higher-tolerance lathe shaft is a necessity.

What's a Morse Taper?

Lathes like the Covington 4000GL, the older Spatzier lathes, or Merker lathes all have an interior tapered shaft on the lathe. This allows you to mount different spindles into the lathe that accomplish different goals, like mounting diamond wheels, leaded center stone wheels, or even using diamond points on the lathe.

The Morse taper is the style of taper on the interior of the shaft. The matching taper on the spindles allows you to "push" the spindle into the lathe shaft, which will hold it in place while you work. The shaft will have an ejector slot in which you use a small metal ejector to "release" the spindle from the shaft when you need to change spindles.

Larger cutting lathes, like the Covington 4000GL, use a Morse 3 taper, while smaller engraving lathes typically use a Morse 1.5 taper.

What Type of Abrasive Wheels Can the Lathe Use?

Grinding and engraving lathes can use any abrasive wheel you generally come across.

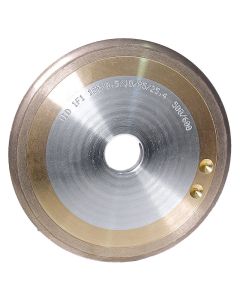

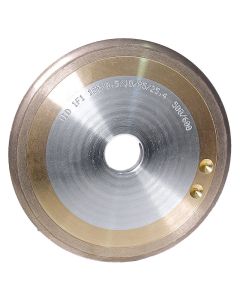

From electroplated to sintered diamond, diamond wheels are the most commonly used abrasive wheels for lathe grinding. Long-lasting and consistent in their grinding, diamond wheels are easy to use, quick to clean up from, and widely available in various diameters and profiles, from cutting to engraving wheels.

Stone wheels are less widely used than in the past but are still an excellent choice for most finishing work on the glass. These wheels are used with a threaded spindle where the arbor on the wheel is created by pouring molten lead in the center and then threaded onto the spindle. These wheels are more difficult to maintain as they must be trued and balanced every time you mount them before each use.

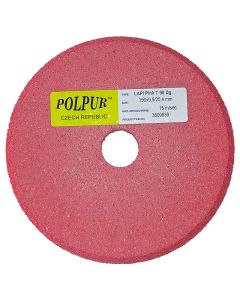

More modern alternatives to stone wheels are finishing wheels like the Polpur aluminum oxide embedded Lapi-T wheels or the diamond resin wheels.

Login and Registration Form